SUMMIT INDUSTRIAL PRODUCTS

MORCON-10 DESCALER

Morcon-10 was developed to remove cement and other calcium materials (lime-scale, barnacles, mussels) from places where they may cause a problem. Morcon-10 is a hydrochloric acid solution that contains corrosion inhibitors, detergents, wetting agents and degreasing compounds. It is designed to penetrate encrusted scale, cement, and barnacles and quickly remove them from the surface. When used as directed, Morcon-10 may be safely brushed, mopped or sprayed on equipment and structural surfaces. It may be circulated through pumps and exchangers. Parts may be soaked. It is non-toxic, non-corrosive, non-flammable and non-hazardous when used as directed. Because it is biodegradable, standard disposal procedures may be followed.

Recommended Usage

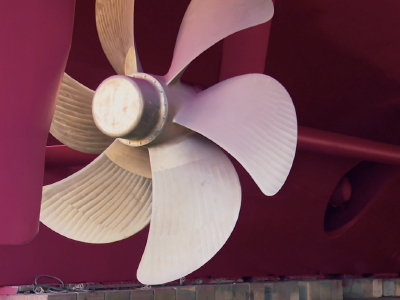

Morcon-10 was developed to remove cement and concrete from trucks, building forms, concrete mixers, pumps, and all sorts of construction equipment. It can also be used to clean excess mortar from bricks, tile and concrete blocks; remove barnacles from propellers, skegs, rudders, and hulls of sea-going vessels; remove barnacles and mussels from pipe, screens, pumps, and exchangers in power plants; and remove rust and stains from floors and process equipment. Morcon-10 is not recommended for use on aluminium, certain alloys, zinc, and alloys of magnesium. The improper use of Morcon-10 could result in the discolouration of an automotive paint finish.

SUBLIME DESCALER

Sublime® Descaler is a water-based solvent with wetting agents, corrosion inhibitors and degreasing compounds. It has a pleasant citrus-lime fragrance that masks the obnoxious odours normally associated with dissolving water scale and corrosion. Sublime® Descaler is low-foaming and quickly releases the carbon dioxide (CO2) gas generated by the reaction of limescale with Sublime®.

Sublime® descaler comes in a pale yellow colour that changes to a deep bluish-purple when it is spent. The advantages of this colour change are:

1. Know when the solution is spent and should be discarded

2. Don’t spend time circulating a spent solution

3. The colour change occurs at a pH of 5.8 to 6.0 which is well within the safe disposal range of most of the current governmental waste regulations.

If the equipment is clean and Sublime® has not changed colour, you can save it and use it again.

Recommended Usage

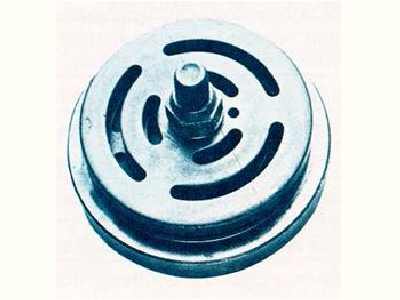

Sublime® Descaler is designed to penetrate and remove encrusted limescale, rust, corrosion products and dirt from water-wetted surfaces in process equipment, commercial and industrial applications. Sublime® is most effectively used by circulating through the equipment to be cleaned. When possible, circulation should be up-flow. Sublime® can also be used by filling the equipment to be cleaned and allowing it to sit until the scale has disappeared. The cleaning operation normally takes two to six hours. It is non-toxic, non-corrosive, non-flammable and non-hazardous when used as directed. Sublime® descaler is registered as NSF-A3 and U.S.D.A. approved as specified in 40 CRF 261. and D.O.T. 173.240(a).

Before

After

ALIMEX DESCALER

Alimex is a water-based chemical formulated to safely clean limescale and corrosion from water-wetted surfaces. It contains wetting agents, corrosion inhibitors and degreasing compounds to help penetrate and carry away the scale and corrosion. This product is specifically designed to be used on equipment that contains aluminium that cannot be safely cleaned with other scale removing compounds.

When used as directed, Alimex is non-corrosive and will not affect the following: aluminium, stainless steel, carbon steel, brass, admiralty metal, copper, iron, lead, PVC plastic, polyethene, rubber leather, and most materials found in water-wetted equipment. Alimex is not recommended for zinc, galvanized steel, or alloys of magnesium.

ALIMEX is non-toxic, non-corrosive, and non-flammable when used as directed. It is biodegradable and can be safely put into the sewer in the spent condition. It also has a built-in indicator which changes colour when the solution is 95+ percent spent. When the solution begins to turn blue, it should be added to or changed if the equipment is not clean.

Recommended Usage

Alimex is a water-based chemical descaler formulated for the safe removal of scale from water-wetted aluminium surfaces. Aided by wetting agents, corrosion inhibitors and degreasing agents, it effectively loosens and removes deposits from critical aluminium components such as heat exchangers, fin fans, and any other aluminium coated surface.

EQUIPMENT VARNISH CLEANER

The use of petroleum lubricants, mainly automatic transmission fluid (ATF), in rotary screw compressors, rotary vane compressors and other high-temperature equipment, results in varnish and carbon formation.

The varnish and carbon deposited throughout the equipment can cause many serious operational problems, resulting in excessively high maintenance costs. Varnasolv can help reduce the problems caused by varnish and carbon. Varnasolv should be added to the existing lubricant to remove and suspend varnish while the equipment is running. Using Varnasolv eliminates the need for disassembling the equipment for cleaning. For maximum benefit, use Varnasolv before each lubricant change. Varnasolv is NSF Registered HX-2.

Recommended Usage

Varnasolv is recommended in rotary screw air, gas and refrigeration compressors, centrifugal compressors, gearboxes, diesel and natural gas engines, and hydraulic systems. Additional applications for Varnasolv include cleaning high-temperature chains. Varnasolv can also be used for cleaning Heat Transfer systems with temperatures up to 400°F.

Varnasolv HV is blended to a higher viscosity for minimal dilution when used in gearbox lubricants.

How to use Varnasolv

Add one gallon of Varnasolv concentrate to every ten gallons of oil in the unit, first draining enough oil to allow adding the Varnasolv. Continue to run the equipment for 20 to 40 hours, allowing the treated oil to disperse and suspend the varnish. To avoid redepositing the suspended contaminants, drain the oil while warm and replace filters. Refill with new oil.

Packing: Varnasolv is available in cases (six gallons), five-gallon pails or 55-gallon drums.

Before

After

FEEL FREE TO TALK TO US

Can’t find the product that you are looking for? Email or call us and tell us what you are looking for.